Allgemeines Projekt

Prototype of an electronic device to measure tissue oxygen saturation using textile-embroidered polymer optical fibers

Pressure injuries (PI) are tissue lesions, which heal very slowly and pose a high risk of serious infections. It also causes severe suffering, and it is expensive to treat. Tissue oxygen saturation (StO2) is a crucial factor in PI development, since tissue hypoxia may lead to tissue necrotization. Such hypoxia is often caused by externally applied pressure to the tissue, which quickly reduces the StO2. Hence, the best therapy is in preventing them. A dangerous situation can be detected, by measuring StO2 using near-infrared spectroscopy (NIRS) and textile-embroidered polymer optical fibers. The electronic device requirements are very specific. Therefore, no available product can be used for doing the research, meaning that a dedicated development is needed.

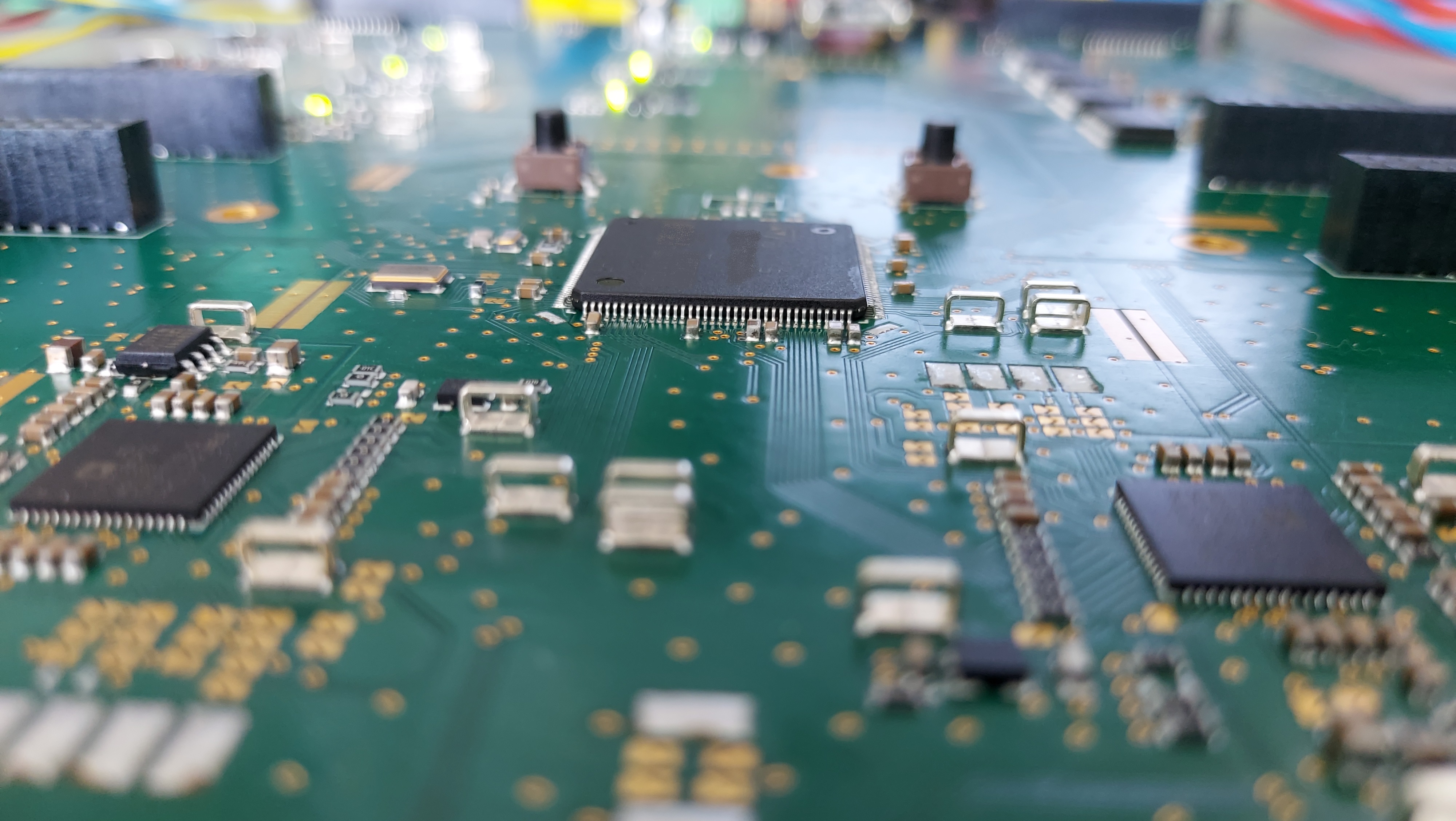

The result is an electronic device that emits near-infrared light at different wavelength and detects them synchronously at different detection points. Two banks with 16 high-powered LED light sources are controlled by a current source in the range of 0 to 3 amps such that each light source can be controlled individually. Minimum power dissipation and maximum optical output are the goals here.

The detection is done by eight receivers, which must be measured synchronously. Due to the extremely different attenuations of the multiple measurement paths through human tissue, a very high dynamic range had to be implemented to allow the electronics to handle the 8 highly sensitive photodiodes. To set the suitable gain of the photodiodes, an adjustable voltage source is used. A temperature sensor allows the device to compensate for temperature dependencies. The two banks of 8 photodiodes are connected to special amplifiers. Since very high brightness fluctuations from pulse to pulse are possible, the bandwidth of the receiver and amplifier must be adequate. The amplified signals are converted by two simultaneously sampling ADCs. Both ADCs work with a sampling rate of over 100 kSPS and the 32 current sources are controlled by a STM32 microcontroller. Because of high data rates, DMA controllers are used. The signals are digitally filtered and streamed to a computer, where further processing is applied to extract the StO2 values.

The electronic device was handed over to the startup company Sensawear (www.sensawear.ch) for doing further research.

We wish Oliver Kress (CEO) and his team a good and successful start.

Acknowledgement: This work is financially supported by the SNSF/Innosuisse Bridge Discovery grant no. 20B2-1_180983/1.

Eastern Switzerland University of Applied Sciences OST,

Institute for Electronic, Sensors and Actuators ESA, Buchs (SG), Switzerland

Institute for Microtechnology and Photonics IMP, Buchs (SG), Switzerland

Electronic Team:

R. Grabher, S. Bawidamann, T. Rath, T. Rastija, R. Gohm, G. Piai

Photonics Team:

M. González, T. Strüning, M. Michler

Empa, Swiss Federal Laboratories for Materials Science and Technology, Laboratory for Biomimetic Membranes and Textiles, Switzerland

N. Ansari, K. Sharma, E. Morlec, M. Camenzind, L. Boesel

Institute for Complementary and Integrative Medicine (IKIM), University of Bern,

Fabrikstrasse 8, 3012 Bern, Switzerland

Startup: Sensawear, Fabrikstrasse 8, 3012 Bern

O. Kress, T. Cantieni, U. Wolf

Duration: 12.05.2022

Team:

René Grabher

ESA Institut für Elektronik, Sensorik und AktorikDozent für Elektronik

+41 58 257 34 18rene.grabher@ost.ch

Thomas Rath

ESA Institut für Elektronik, Sensorik und AktorikWissenschaftlicher Mitarbeiter

+41 58 257 31 33thomas.rath@ost.ch

Rainer Gohm

ESA Institut für Elektronik, Sensorik und AktorikTechnischer Mitarbeiter ESA

+41 58 257 34 19rainer.gohm@ost.ch

Tina Strüning

IMP Institut für Mikrotechnik und PhotonikWissenschaftliche Mitarbeiterin

+41 58 257 31 94tina.struening@ost.ch

Marcos González Rodríguez

IMP Institut für Mikrotechnik und PhotonikWissenschaftlicher Mitarbeiter

+41 58 257 31 95marcos.gonzalez@ost.ch

Prof. Dr. Markus Michler

IMP Institut für Mikrotechnik und PhotonikProfessor für Physik und Photonik Leiter Kompetenzbereich integrierte Optik, Profilleiter Photonics

+41 58 257 34 64markus.michler@ost.ch

Prof. Guido Piai

ESA Institut für Elektronik, Sensorik und AktorikProfessor für Elektrotechnik und Elektronik

+41 58 257 33 91guido.piai@ost.ch

Participating Institutes:

ESA Institut für Elektronik, Sensorik und Aktorik