Since 2020, we own and operat our own wind turbine on Taggenberg (Winterthur ZH). To quickly test equipment and new ideas, we operate a small wind turbine. In addition, we own and operate a small-scale wind tunnel.

We have purchased a wind turbine at Taggenberg, Winterthur (ZH). It is a light wind turbine AV-7 of the company Aventa AG from Switzerland, with three rotor blades of 6 m length and a nominal power of 6 kW. The turbine was put into operation in December 2002. The average annual wind speed at hub height is about 3.0 m/s, which results in an electricity yield of about 12'000 kWh/a.

We plan to use this turbine for various research projects and for teaching. We are already testing our MEMS pressure measurement system "Aerosense" on the rotor blades. We also offer the facility for external research projects and tests. We look forward to hearing from you!

To quickly test equipment and new ideas, we operate a small wind turbine. The «Windflower» is efficient, quiet and also looks nice. With a diameter of 2 m, it generates up to 1 kW of power, which can be fed directly into the electricity grid.

We have used the «Windflower» for student blade design project as well as to test blades made out of biomaterials.

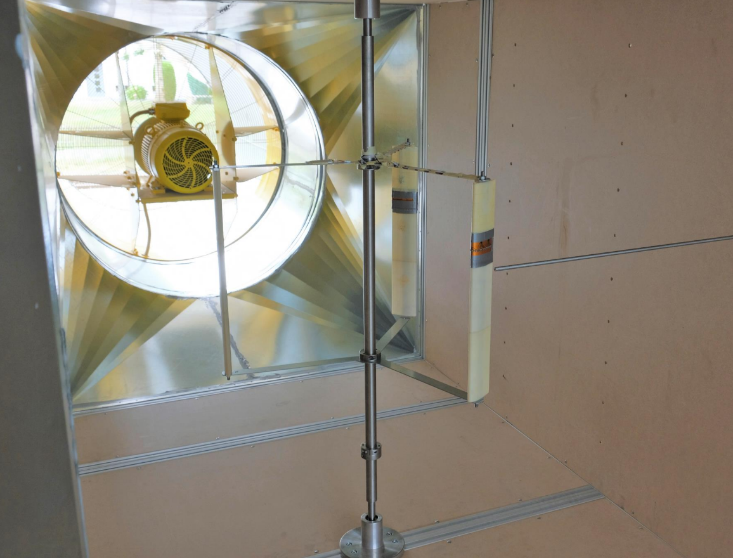

We own and operate a small-scale wind tunnel, which allows us to measure the flow around airfoils and small wind turbines. As part of the Aerosense project, for example, we have tested the electronics and Bluetooth connection by attaching the measurement system to a rotating small wind turbine, as well as compared the pressure measurements to conventional pressure taps built into a NACA airfoil model.

About us

Collaboration

Events

News (in german only)

Newsletter

Divisons & Employees

Dr. Sarah BarberIET Institut für EnergietechnikHead of Wind Energy Innovation Division, Lecturer

+41 58 257 42 62sarah.barber@ost.ch