Hardness testing

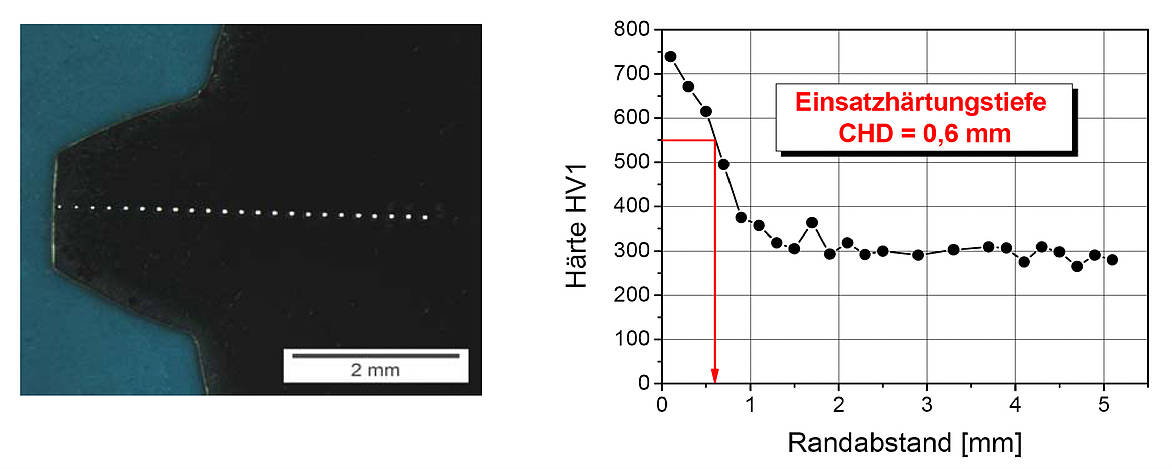

Application example «Hardness curve»

The wear and load capacity of a gearwheel are highly dependent on the local strength of the material. For many metallic materials, the strength can be specifically changed, e.g. by suitable heat treatment. Hardness (resistance to plastic deformation when impressed by a harder test specimen) is an easily accessible measurand for assessing the local strength of a material.