Research project

SmartHiFe2 - A novel iron-catalyzed biogas upgrading concept

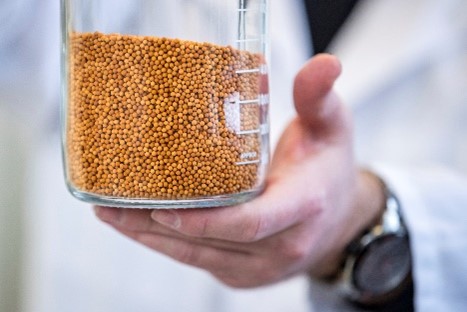

At UMTEC, our team focuses on the development of a novel and efficient power-to-gas technology for the production of renewable methane. With the newly developed sorption-based methanation technology, it is possible to process biogas into high-quality renewable methane that can be fed directly into a gas grid.

Net zero emissions by 2050

Switzerland has set itself the goal of reducing greenhouse gas emissions to net zero by 2050. To achieve this goal, replacing fossil fuels with renewable resources is an essential way to offset CO2 emissions. Biogas from waste in Switzerland has a great potential to diversify the energy matrix, with an available energy yield of 52.8 PJ/year. In addition, the Swiss gas industry is aiming for a massive increase in the use of renewable methane by up to 30% in 2030. Conventional biogas sources (e.g. digesters) are usually operated at low temperatures, atmospheric pressure and low gas hourly volume flows (GHSV). Gas mixtures from such sources need to be compressed and heated with conventional catalysts in order to be upgraded, causing an important change in operating parameters in the production process.

Translated with DeepL.com (free version)

Our project

The main objective of SmartHiFe2 is to develop a highly efficient sorption-assisted methanation technology for upgrading biogas to overcome the remaining obstacles on the way to industrialization. These obstacles are the cost of the catalytically active Ni metal and its sensitivity to sulphur. Scientific penetration is therefore focused on a technologically and economically reliable system and its upscaling. Fe-based materials are excellent candidates to replace Ni as they are cheaper and more environmentally friendly. Aspects such as material design and optimization as well as process development are being investigated to ultimately bridge the gap between laboratory and industry.