Assembly production

The ESA infrastructure enables the in-house production of functional samples, prototypes and pre-series, which are essential for the rapid implementation of electronics projects. The infrastructure covers the entire value chain, starting with our automatic dispensing of solder paste, through the fully automated placement of the smallest components with optical inspection, to the soldering of assemblies in a 100% inert environment.

Thanks to the fully automatic dispenser and optical placement system, the assembly can process the smallest QFN and BGA components. Pad distances of less than 0.5 mm and solder paste dot diameters of 0.13 mm are possible. The vapor phase soldering system enables the soldering of assemblies with lead-free soldering with perfectly homogeneous temperature distribution on the assembly. Overheating of individual areas of the print is ruled out by the process. The result is high-quality functional samples and pre-series.

Additional soldering equipment is available in the laboratory park. If you have a need for prototype production or would like to assemble your own prototypes in-house, we will be happy to answer your questions.

Hier geht es zum Onlineportal für Bestellungen für die Baugruppenfertigung

The ESA Institute has the following equipment:

IR Reworkstation – HR 550 ERSA

- Temperature detection via 2 channels: 1 IRS sensor, 1 AccuTC thermocouple (K-type)

- Manual reflow head with automatic component extraction

- 2 high-quality PAL CCD cameras (18 x optical and 4 x digital zoom)

- Manual component handling (from 1 x 1 mm to 40 x 40 mm in size)

IR Reworkstation – PDR X-PDR-IR-E3M

- Temperature detection via 2 channels: 1 IRS sensor, 1 AccuTC thermocouple (K-type)

- Manual reflow head with automatic component extraction

- 2 high-quality PAL CCD cameras (18 x optical and 4 x digital zoom)

- Manual component handling (from 1 x 1 mm to 40 x 40 mm in size)

Pick and place machine M10V Paggen

SMD placement machine for prototypes

The M10V pick and place system is a flexible pick and place machine for placing SMD components with edge lengths of 0201 to 40 x 40 mm. The placement itself is always carried out with a vacuum suction cup, which explicitly measures the components via a vision system and then places them with high precision. The machine is a sophisticated, high-quality and stable design. The simple programming and the excellent price-performance ratio make the M10V perfect for small production lines and prototype construction. The M10V pick and place machine combines mechanical precision with the highest quality. The easy-to-use and flexible programming software enables maximum flexibility with high productivity. Fast set-up times and minimal maintenance requirements contribute significantly to reducing the total cost of ownership and thus ensure a rapid return on investment. Unique features of the M10V include the pick-up of large components even from undefined trays and the processing of bulk material (birdseed). The intelligent head vision system makes it possible to find and pick up these components, align them with the help of the vacuum suction cup and place them precisely using the table vision system. The entire usable area can be equipped with PCBs or freely definable feeders. The automatic feeder cassettes are intelligent and can be attached from the outside in just a few simple steps. Alternatively, the M10V can be equipped with a time-pressure controlled dispenser for solder paste and SMD adhesive.

Stereo microscope with integrated 10 MP camera S9I LEICA

- with integrated 10 MP camera

- 10° Greenough optical system

- 9:1 apochromatic zoom

- Viewing angle 35°

- Magnification 6.1x to 55x

- Max. Resolution 500 LP/mm

- Working distance 122 mm with basic equipment Object field diameter 37.7 mm and adjustable zoom limit with click stops 10x, 20x, 30x, 40x and 50x

- 50-76 mm eye relief with FusionOptics for 3D view with 12 mm depth of field and 37.7 mm object field

- FusionOptics: beam path left high depth of field - right high resolution

- Integrated digital camera: CMOS sensor, 35 images per second, 10 MP resolution for Full HD quality, connections: HDMI, USB and Ethernet

- Power LEDs 1.2 Watt, (4 LEDs for ring light, 3 for oblique lighting) at LED2500 color temperature 6500°K, 25,000 hours average service life

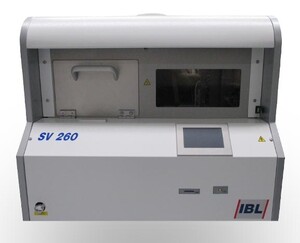

Vapor phase soldering system SV 260 IBL

- Ideal for prototype production, small series and rework tasks

- Adapter for double-sided assemblies

- ReSy, repair unit for QFPs and BGAs

- TE option for external profile recording

- Assembly size up to 300 x 260 x 60 mm

- No overheating of the assemblies, max. soldering temperature of 235°C.

- Automatic 100% inert protective gas atmosphere without the use of nitrogen.

- The components and FR4 circuit boards commonly used today can be used.

- Best possible wetting of the components with lead-free solder pastes.

Stencil printer ZelPrint LT 300 SMT

- Work area: 300 mm x 300 mm

- Accuracy: ±0.025 mm (±1Mil)

Contact us for more information!

René Grabher

ESA Institut für Elektronik, Sensorik und Aktorik Dozent für Elektronik

+41 58 257 34 18 rene.grabher@ost.ch