Microtechnology meets Optics

Optical waveguides, miniaturized couplers, thin film filters and micro mirrors are becoming increasingly important.

We have the right solutions for light coupling/decoupling into glass fibers for miniaturized optical sensors. Furthermore, our competencies include optical metrology and simulations, e.g. for specialized optical coatings.

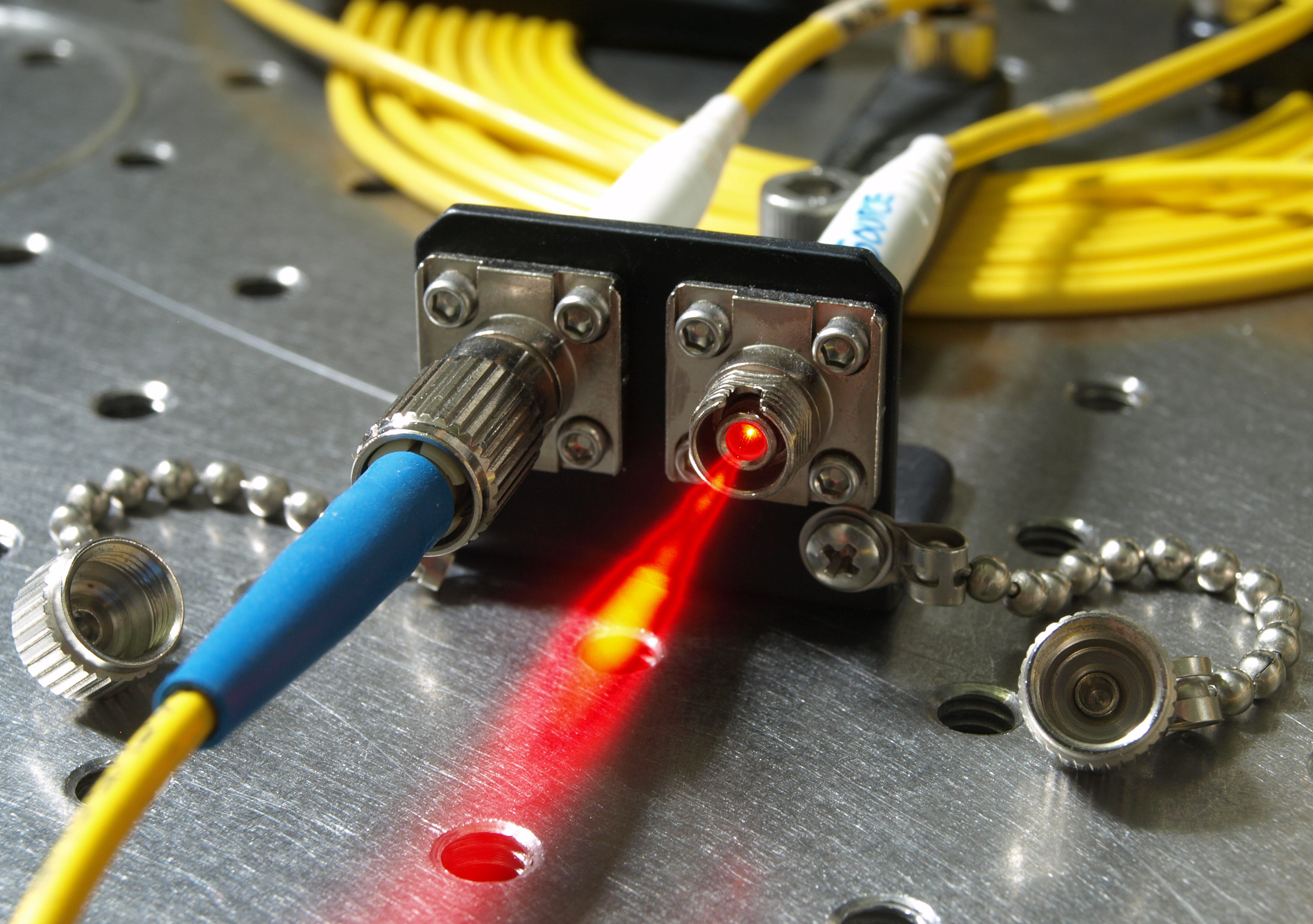

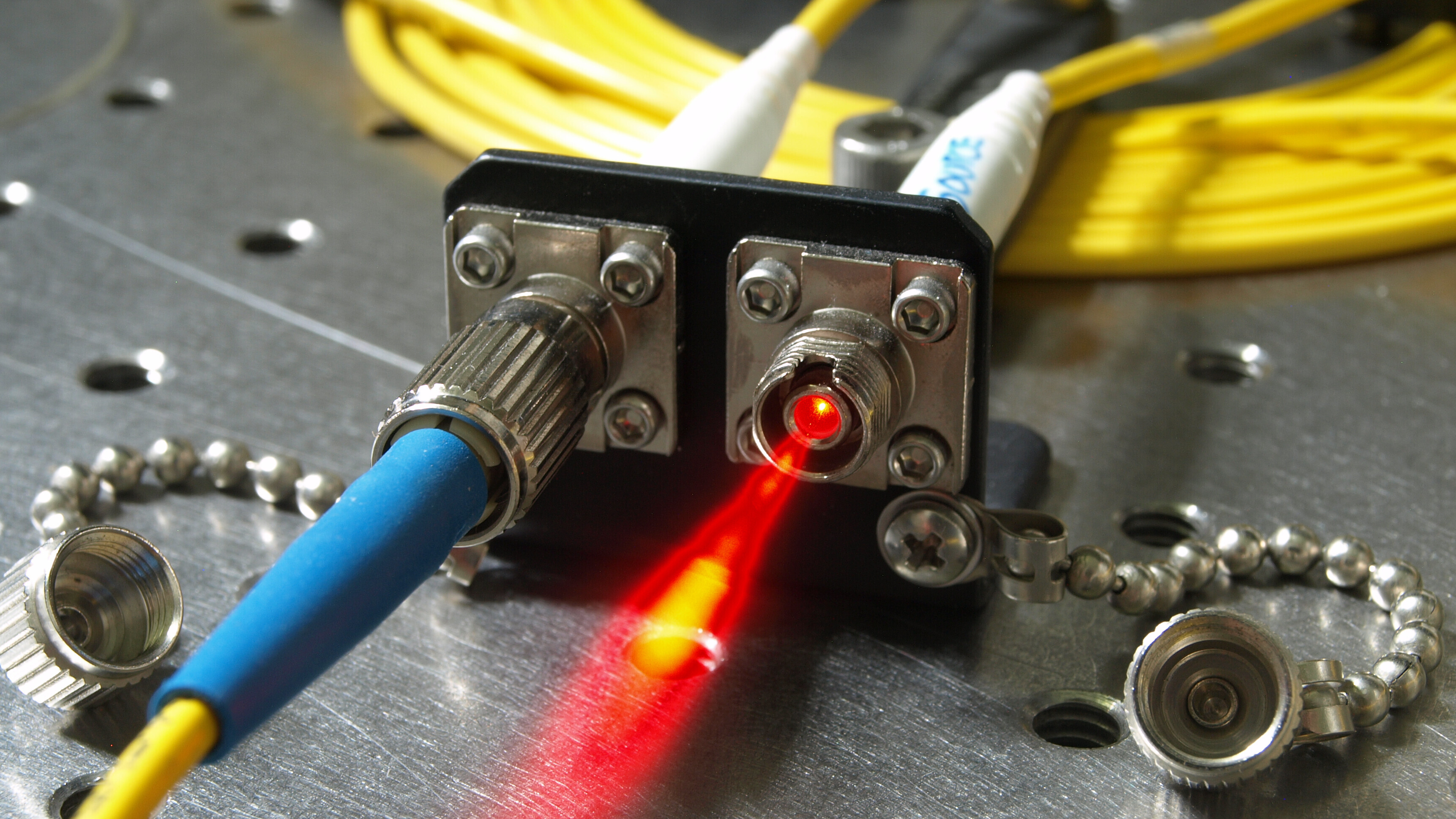

Fiber Optics

Assembly of Optical Fibers

From bare fibers to fiber patch cords

We manufacture fibers according to your requirements. Equipped with all necessary equipment, from splicing and stripping tools to various fiber cleavers for end face preparation and connector polishing machines, we manufacture your individual fiber solution.

We have all sorts of solutions for you at hand including SMA, FC-PC and FC-APC plug connectors, grin lens packages, bare fiber bundles, fiber splices and tapered fiber end faces.

Telecom Fiber Optics

Because of minimal optical losses and superior dispersion characteristics the C-band (1500 nm - 1600 nm) is the spectral range manly used in optical telecommunication applications. As a partner for projects and service provider we have a wide assortment of telecommunication equipment at hand.

- C&L-band ASE sources (1500 nm - 1600 nm)

- Tunable laser sources

- Telecom fibers (SM-9/125)

- IR free space and fiber detectors

- C-band polarisation controller

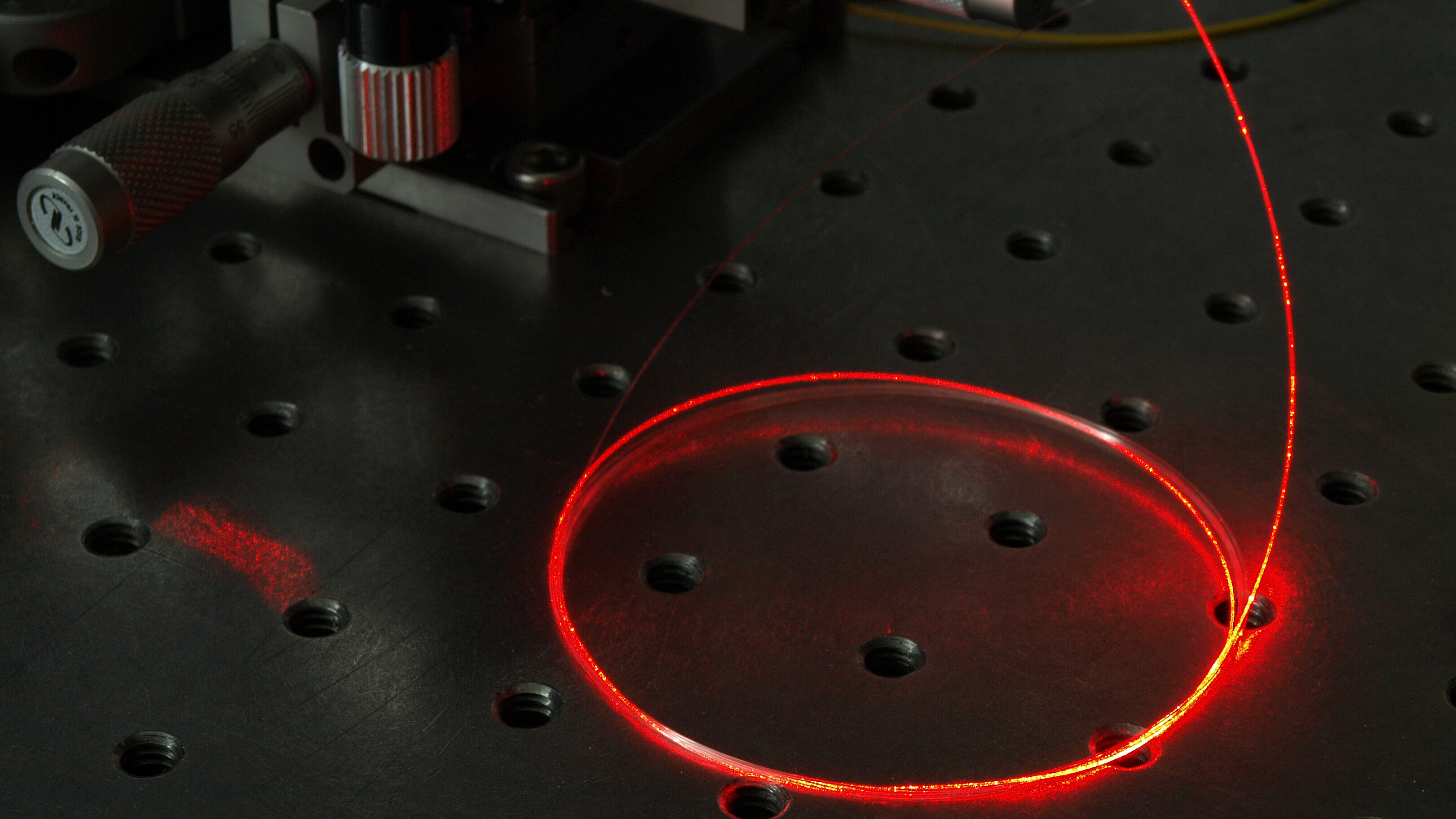

Fiber Optical Measurement Technology

The term fiber optical measurement technology is understood to mean measurement methods where fibers are used to transfer light from the source to the measurement object and from there to the detector. The detection mode can either be integrally or spectrally resolved. For such purposes we have a range of single- and multimode fibers as well as custom made fiber assemblies (collimators with ball and grin lenses etc.) at our disposal.

At the other end of the line we have special fiber detectors based on the principle of an integrating sphere to measure divergent radiation at the fiber output. Fiber coupled spectormeters allow us to measure the spectral properties ranging from VIS to IR (1700 nm). To measure the polarisation of light in the VIS range a polarimeter is available.

Integrated Optics

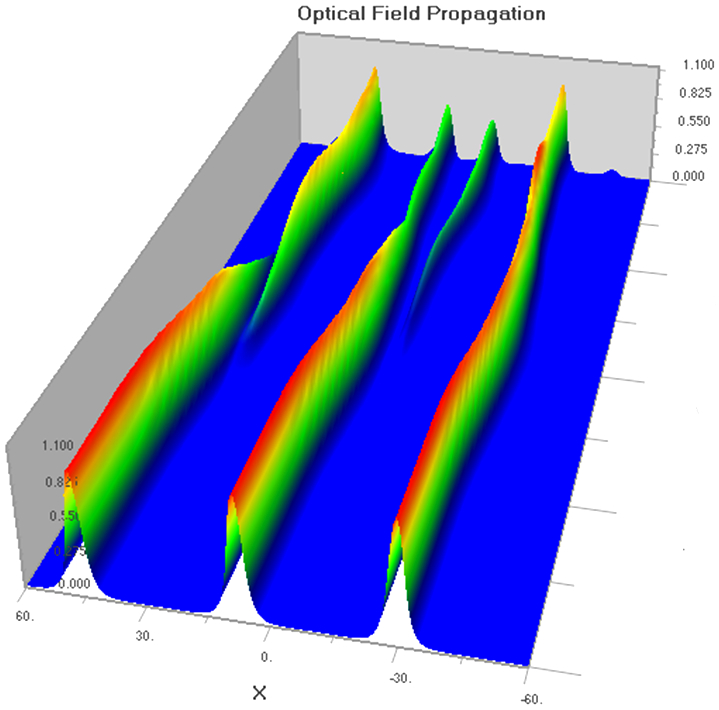

Waveguide Simulations

It doesn't matter whether you are interested in the single- or multimode range we can provide suitable software tools for any application.

To model multimode waveguides we mainly use the non sequential mode by Zemax. It allows to simulate the propagation of rayse through any desired geometry and to detect them at any definable place. To get accurate results the investigated structures need to be at least 10 times the size of the wavelength. Therefore the ray tracing method is only suitable for multimode systems with diameters larger than 50 µm.

When modelling singlemode waveguides or fibers wave-optical phenomenons (like diffraction and interference) need to be taken into consideration. There is a BPM software package for guided wave optics called BeamPROP by Synopsys/RSoft. There are two methods available. The mode-solver allows do calculate the energy distribution along the waveguide's cross section. The beam propagation method on the other hand can model the field distribution across the desired component. BeamPROP can solve 2D as well as 3D problems.

Fabrication of Waveguides

In the case of fabricating waveguides we mainly rely on external partners. We maintain a close cooperation with companies like Variooptics AG in Heiden. vario-optics ag is specialised in the fabrication of polymer waveguide systems using direct writing techniques or mask exposure.

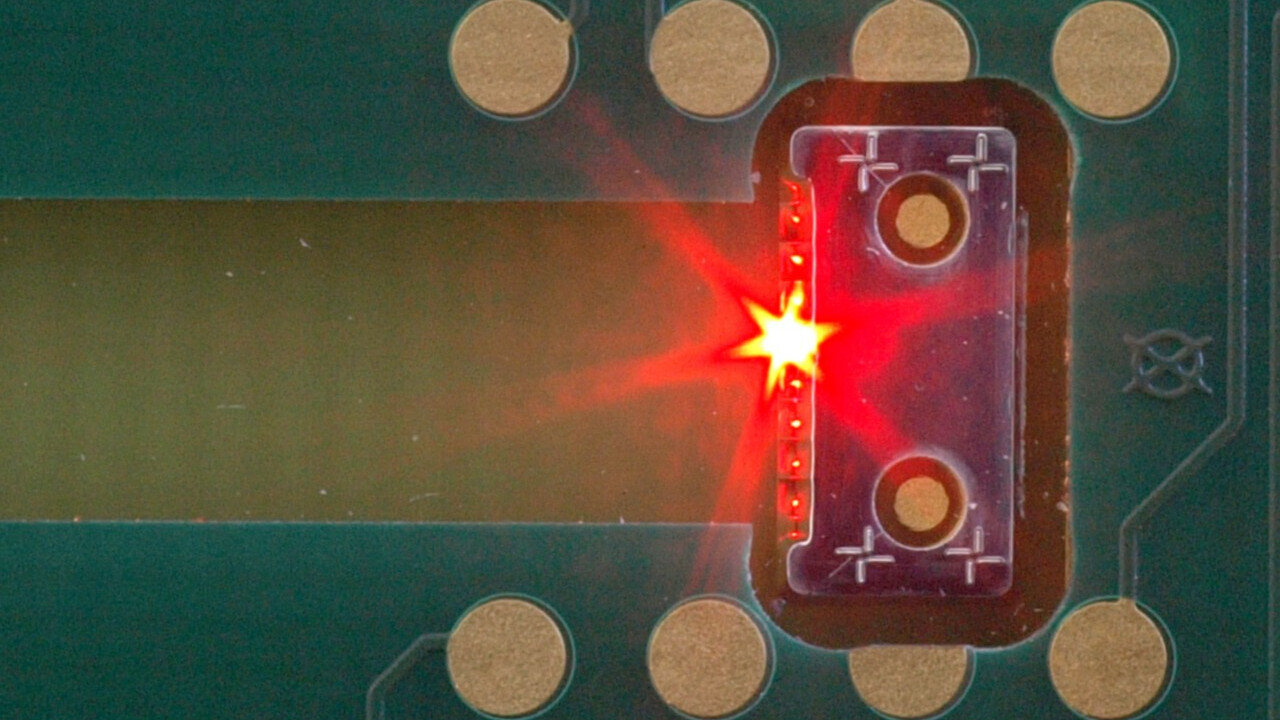

State of the art producible multimode waveguides have a cross section between 50 μm and 400 μm. Based on this technology an electro-optical circuit board has been developed in a cooperation project. These OECB technology can be used to implement datacom and sensor applications.

Characterization of Waveguides

Among the most important characteristics in integrated optics are transmission and loss measurements to determine the attenuation properties. For that usually the cut-back method is used where the attenuation of a waveguide is determined by measuring the transmission of varying lengths of waveguide pieces. Since the geometry and the side wall roughness of the waveguide's core have a strong influence on the losses the geometry has to be optimised (by simulation) and the roughness has to be determined (by white light interferometry).

The further characterization of waveguides include the measurement of the mode-field using a beam-view camera and divergence or numerical aperture of a waveguide. In the process of developing waveguides thin film analytics is a decisive factor. Values like film thickness and refractive index of the applied materials provide important information about the quality and properties of the produced waveguide layers.

Prof. Dr. Markus Michler

IMP Institut für Mikrotechnik und Photonik Professor für Physik und Photonik Leiter Kompetenzbereich integrierte Optik, Profilleiter Photonics

+41 58 257 34 64 markus.michler@ost.ch