Research project

Solar Device

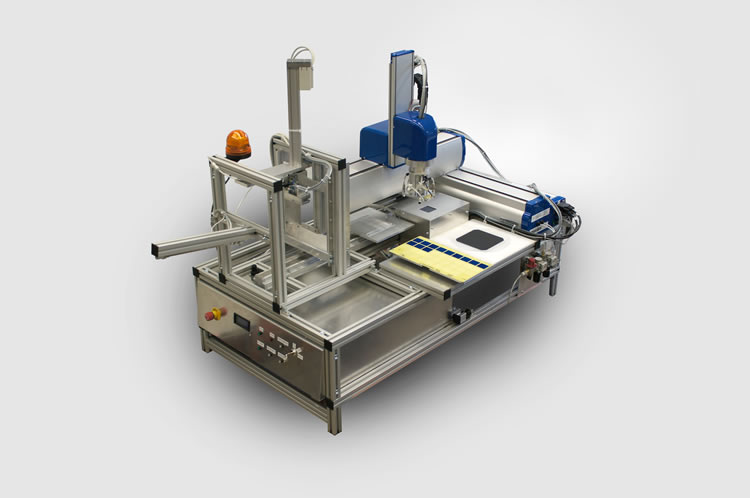

Process station for detaching photovoltaic cells from the carrier film for subsequent processing for applying the solar elements to textiles.

Process automation in the manufacture of robust miniaturised solar elements

» Video "Solar Device" Solarcell Peeling Device

In collaboration with the Universities of Applied Sciences of Buchs, Lucerne and Rapperswil, the industrial partners Forster Rohner AG, Daochu AG (e5Solar) and Altatec Micro Technologies AG, miniaturized solar panels were produced as part of the CTI-Project "Solar Device" by smart combination of existing technologies. By attaching solar elements on fabrics with conductive yarn, it is possible to generate fully flexible fabrics with photovoltaic capabilities. For example, the outside of a handbag can be used for charging electrical devices.

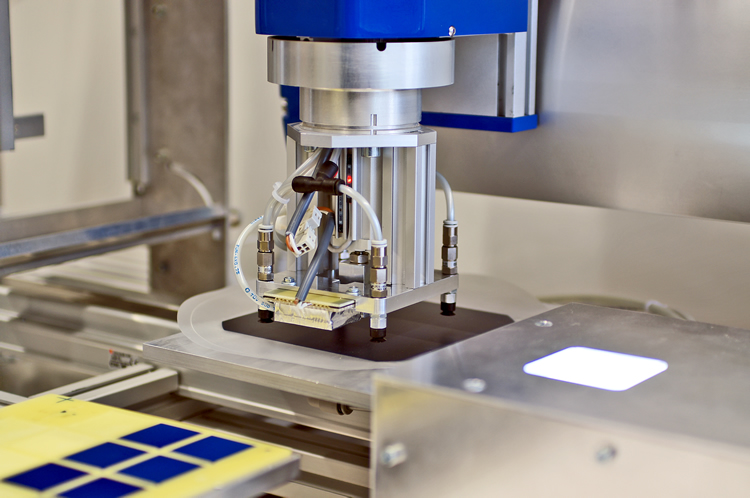

The basic elements for these miniaturized solar panels are cut from a commercial pseudo-square 6-inch solar cell. For this, the solar cell is adhered to a carrier foil, cut up and then individual elements are finally removed from the film. Due to the adhesive force of the solar cells to the foil, the detachment holds the risk of premature damage. As it turned out, a consistent quality of this process step cannot be ensured when manually performed.

Objective

The task of the ILT, Institute for Laboratory Technology, has been to develop an automated industry-compliant solution for the "detachment of the cell from the film" process step. A corresponding station has to be realized to detach the cut solar cells.

Conclusion / Outcome

In the developed process station solar cells of different sizes and thicknesses can be detached from the carrier film. The station consists of three main components, a handling robot, an image processing unit and the newly developed "peeling device", which separates the cell from the film by pulling the film through a 90° angle. In addition, the process reliability is increased by an early recognition of damaged cells. The modular design of this station allows an easy and rapid integration into an industrial production chain.

Core themes of the project

- Industry-compliant process automation

- Modular design

- Image processing with application-specific lighting

- Control by embedded microcontroller

Funding:

Innosuisse

Partner:

Hochschule Luzern, Forster Rohner Textile Innovations, Altatec Microtechnologies AG