Tensile, compression, bending tests

Zwick 1445-03

- Measuring cells: 500 N and 10 kN (HBM)

- Fine strain transducer: mechanical

- Climatic chamber: RT ... +200°C

- Especially suitable for testing plastics, sensitive wires etc.

Zwick Z100 TN ProLine

- Measuring cells: 500 N (HBM) and 100 kN (Xforce)

- Fine strain transducer: videoXtens

It can be determined without contact:

- Strain hardening exponent (n-value, ISO 10275)

- Longitudinal strain and transverse contraction (r-value, ISO 10113)

- Flow curve from quasi-static tensile test

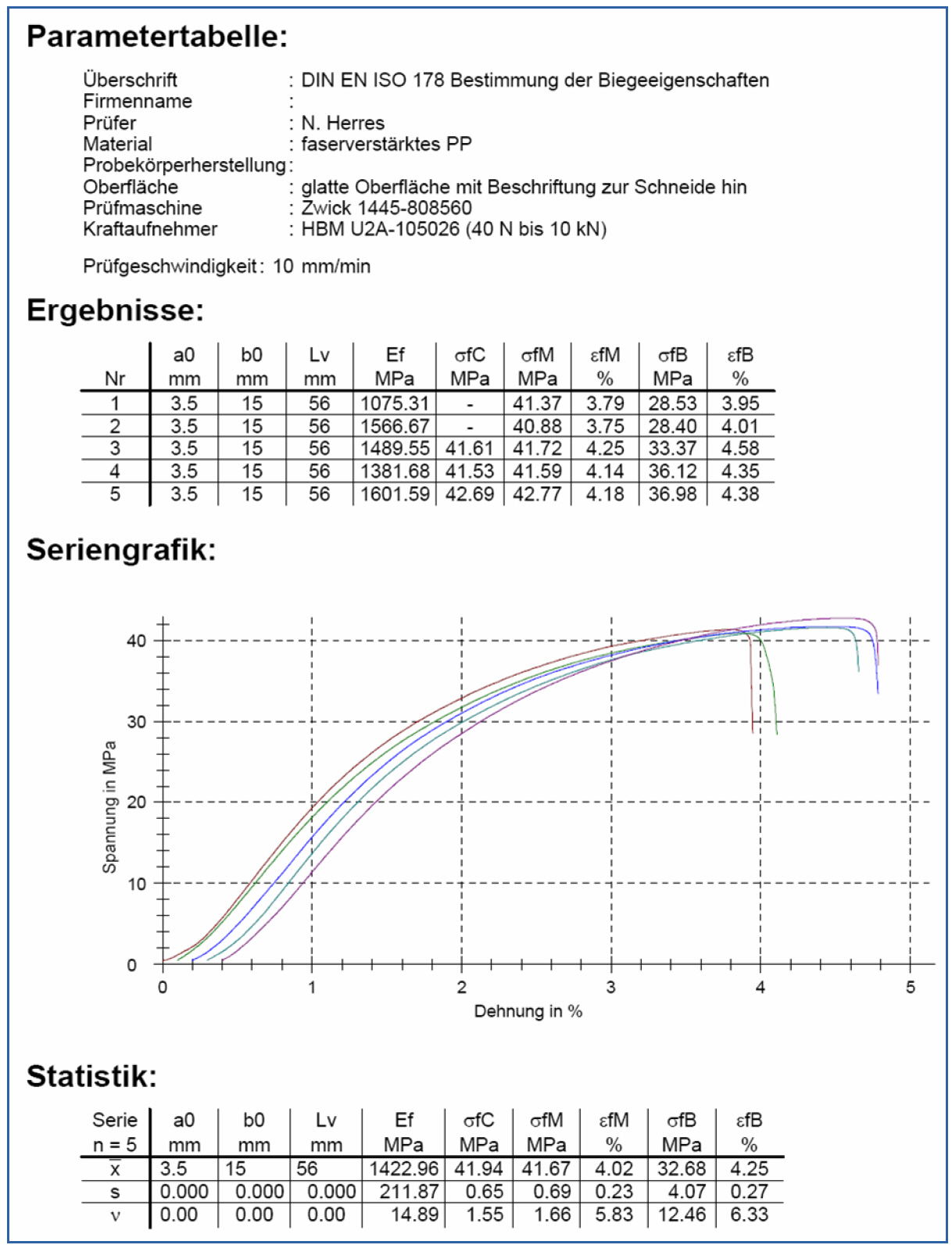

Application example «Bending pressure test»

The bending properties of fibre-reinforced polypropylene were tested in a 3-point bending compression test (DIN EN ISO 178).