We use the optical spectrometer SPECTROMAXx (version M) to determine the composition of metallic samples.

After calibration, very reliable element contents are obtained. Carbon, phosphorus, sulphur and possibly nitrogen are already detected in the ppm range and can be quantitatively determined to fractions of a percent.

By comparing the analysis with values from a connected database, the material designation can be determined. Measuring modules and calibration standards are available for the matrix materials:

Fe, Al, Cu, Ni, Mg, Zn, Ti, Co and Sn.

Typical sample shapes:

The typical spot diameter is 5 mm. The sample must be electrically conductive, otherwise no DC glow discharge will occur. Powder and materials that melt or decompose at low temperatures cannot be measured.

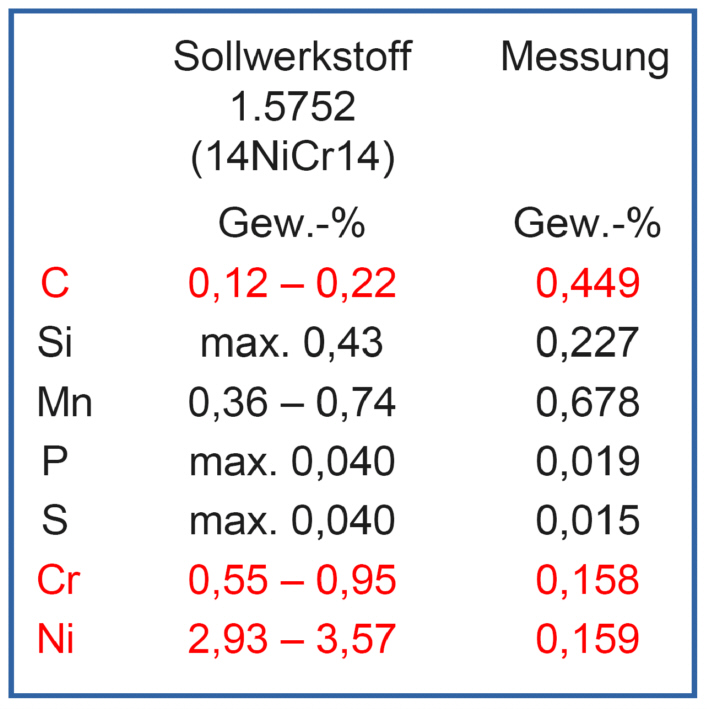

The composition of a steel flat sample was unclear. It was assumed that it was the case-hardened steel 14NiCr14 (in short: «nominal material»).

The spark spectrum shows significant deviations from the target composition for three elements (marked in red). The database suggests the following material C45 (material no. 1.0503)

Jan AllaartIMP Institut für Mikrotechnik und PhotonikExperte für Schadensanalyse

+41 58 257 33 75jan.allaart@ost.ch