Research project

Smart Factory @ Techpark

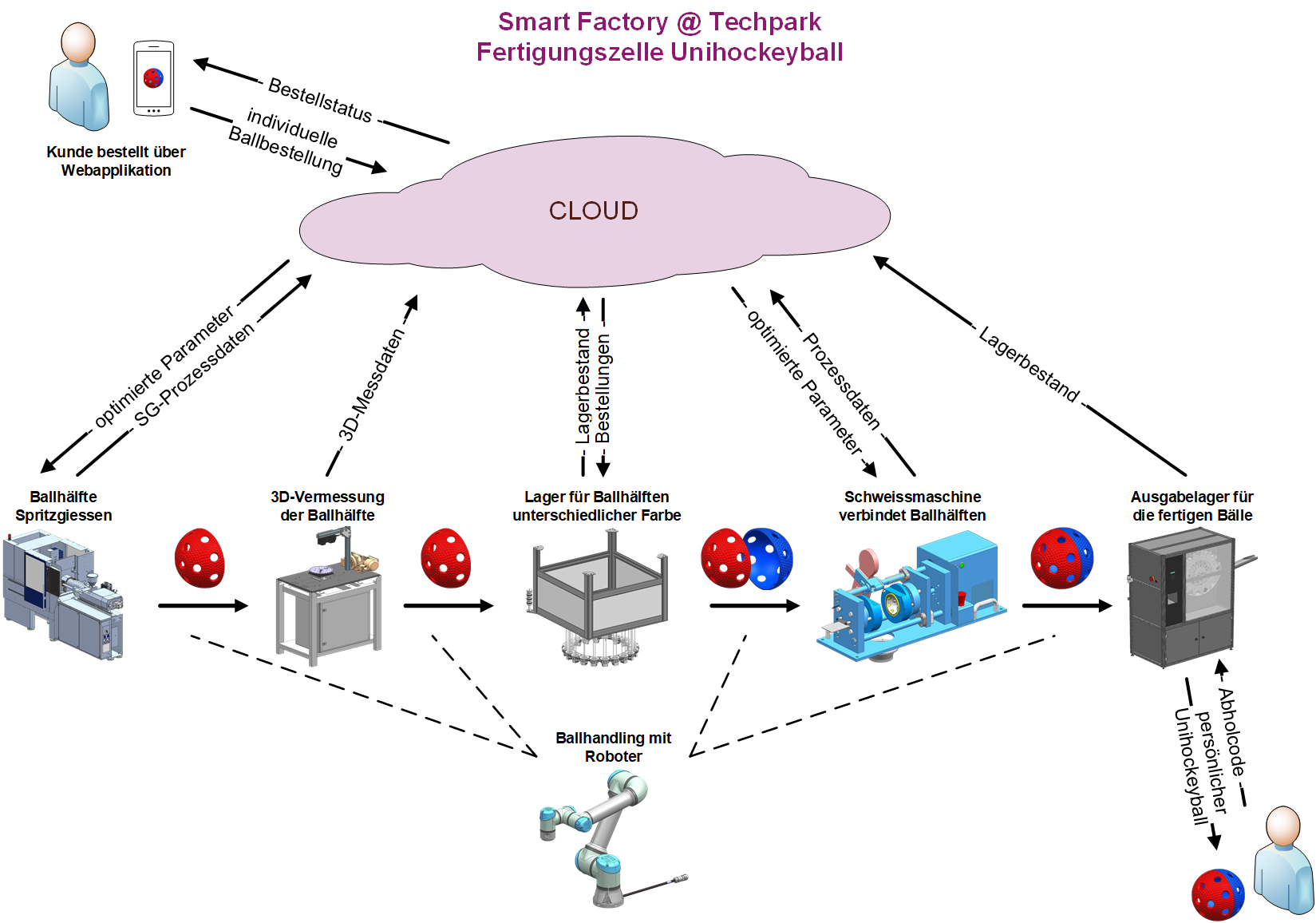

The ILT and other institutes of the OST are currently working on the construction of a Smart Factory in the new Techpark. One highlight will be the fully automated production cell for customised floorballs.

Networking machines

The ILT and the other institutes of the OST have a comprehensive machine park. In the new Techpark, the various machines (robotics, plastics processing, mechanical workshop) are networked with each other to form a smart factory. By networking with various company software (CAD, PLM, ERP), the machine data is brought together with specific design and order data for the products to be produced. This comprehensive database makes it possible to learn for specific use cases and to develop concrete instructions for action in production. Since this autumn, the Smart Factory in the new Techpark has been continuously developed as a unique platform and serves as a showcase for SMEs and for student training.

Automatic component measurement

A highlight of this Smart Factory will be the "Floorball" manufacturing cell. In a fully automated process, floorballs are produced according to customer specifications. The ball halves are removed from the injection moulding machine with a handling system and then precisely measured with a laser scanner. By comparing the 3D measurement data obtained with the stored process parameters and measured variables from the injection moulding process, the optimum production conditions can be determined. A robot stores the measured ball halves in a buffer. In addition to the workpieces that are currently being produced, ball halves in other colours are stored in this warehouse.

Individually designed floorballs

Via a web application, a visitor can use his own smartphone to design and order a floorball individually. The robot in the production cell takes the ball halves of the desired colour from the intermediate storage and transfers them to the welding machine. There, the individual parts are fused together to form the customised ball. Until the visitor picks up his ball, it is stored in the output warehouse's turret storage. Information on the current production status can be accessed online by the visitor at any time. By scanning a QR code on the mobile phone screen, the customer receives his individually designed ball from the output store.

The production cell floorball is currently being realised as part of semester and bachelor theses as well as an inter-institute project. The ILT is mainly concerned with the robotics, the control of the entire system and the system safety. In subsequent projects, the manufacturing cell will be expanded with further modules.

Video zur Smart Factory an der OST - volldigitalisierte Fertigung für die Zukunft

Duration: 01.06.2021

Partner:

IWK, IPEG