Solar Glass

Solar thermal collectors and photovoltaic modules are normally covered by glass sheets as a protection against weathering effects, as insulation or reinforcing element. The efficiency of these products is significantly dependent on the quality of the glazing, because all solar radiation has to be transmitted through the glazing before its transformation to thermal or electrical energy.

On the whole, covers are made out of special solar glass whose distinctive feature is purity in terms of chemical composition. This feature alone makes it possible to achieve a considerably higher light transmission (available energy) than that achieved with normal glass. To the naked eye a good solar glass is hard to distinguish from regular window glass. The effectiveness of a thermal collector or a PV module not equipped with a solar glass cover may therefore be reduced by several percentage points.

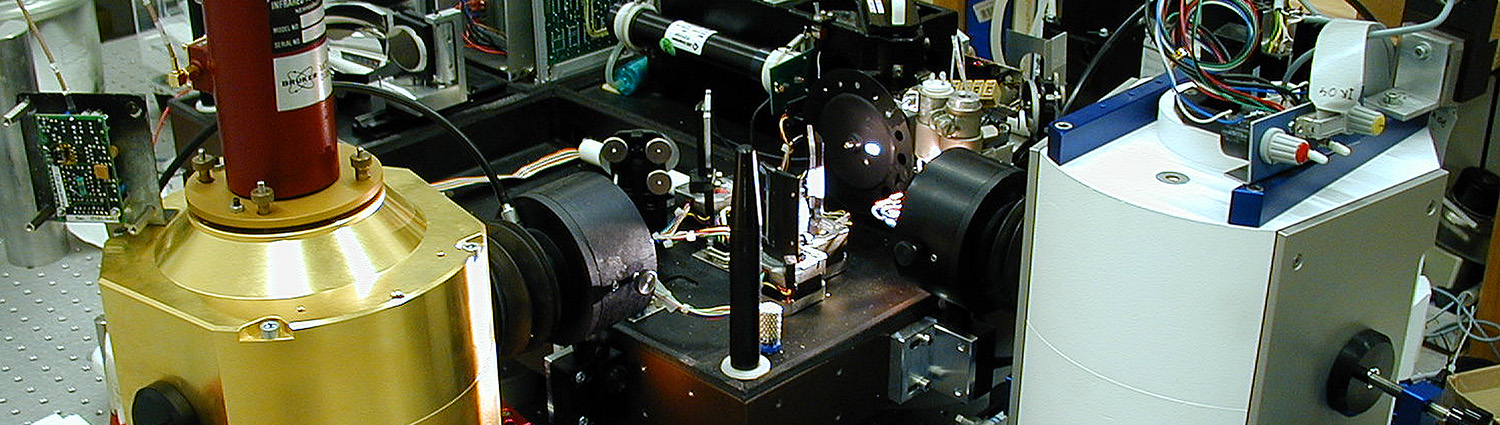

The correct measurement of light transmission is very expensive and requires special spectrometers, sensors and a good deal of experience.

The measurement of structured glasses that are often used in solar energy products is particularly challenging. Also the incident angle dependent transmission can have a significant impact on the annual energy gains of solar installations and therefore should be implicitly considered.

SPF is able to provide you with the required equipment to make these measurements.

Glass Certification

SPF Testing also offers a certification program specially tailored for solar glass.

This certification is especially intended for glass manufacturers and collector/module manufacturers:

- Glass manufacturers

The SPF solar glass certificate is recognized worldwide. Many manufacturers allover the world (solar-thermal collector and PV module manufacturers) rely on the SPF certificate.

- Collector/module manufacturers

Collector/module manufacturers must be able to count on glass quality. The SPF certificate is a key requirement for quality assurance agreements and is often used as a component of manufacturer specifications. Reference glasses may also be submitted for testing.