Forschungsprojekt

Investigate PPGD-spallation and cuttings removal / fluid management

This project aims at developing the cuttings removal and fluid management system specifically for Plasma-Pulse Geo-Drilling (PPGD).

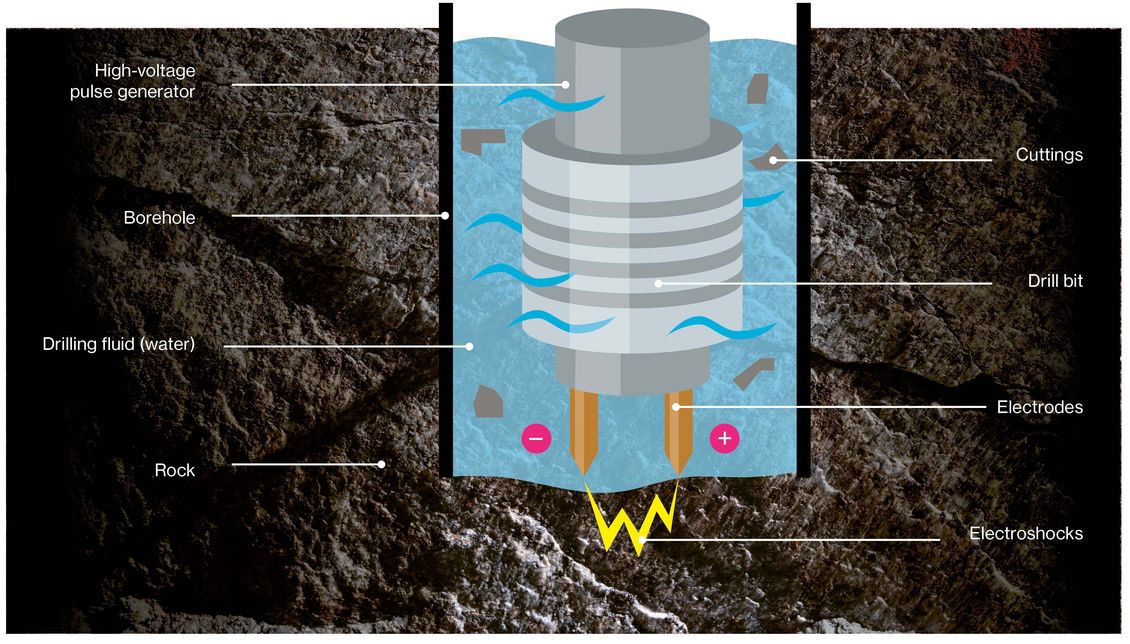

In contrast to traditional subsurface rotary drilling methods, where the cuttings are in the mm size range, the cuttings produced by PPGD, and similar electro/plasma-pulse drilling methods, are with up to 20- 30 mm significantly larger. Removing such large cuttings from 5-10 km deep boreholes requires the development of a specifically designed fluid management system for PPGD. Furthermore, the fluid that is circulated during PPGD currently is demineralized water (required to enable electric arc (i.e. plasma) formation through the rock (Figure 17) and not as a short circuit from electrode to electrode directly through the water). Thus, the demineralized water will need to transport the rock cuttings from the borehole bottom at 5-10 km depth all the way to the land surface.

This SP 11 has the following tasks/goals:

1. Improve the understanding of the PPGD spalling process

2. Investigate the grain size distribution of the PPGD produced rock cuttings for various PPGD parameters 3. Investigate how the rock cutting grain sizes affect their removal by the fluid circulation system

4. Investigate the effects of the borehole cementing/casing on the hydraulic properties of the fluid management/circulation system

5. Estimate the power requirement to transport the rock cuttings to the land surface, based on nu-merical and physical models

Projektpartner:

ETH Zürich

SI KIBAG AG

Geotherm AG

SwissGeoPower AG

Basler und Hofmann AG

Amberg Group AG

Sika Services AG

Laufzeit: 01.01.2022 - 31.12.2026

Projektfinanzierung:

INNOSUISSE (Bundesagentur für Innovationsförderung)